- Products

- ESP-S Protectors

- TJP Protectors

- STP Protectors

- SSP Protectors

- Drilltec Advanced Composite Technology (ACT™) Protectors

- Line Pipe Protectors

- Resist-All Packaging (RAP) Systems

- Econo-Rap Systems

- LE-Rap Systems

- Custom Packaging Systems

- Stabbing Guides

- Secure Tubular Lifting Systems

- Other Products & Services

- Drilltec Marine Division

-

DRILLTEC Products

Drilltec products are manufactured in the United States, Europe, South America, Japan, Southeast Asia, Mexico, China, Russia and the Middle East.

Drilltec is dedicated to maintaining its leadership position in the OCTG industry through continued research and development directed toward better serving our customer’s needs.

All applicable Drilltec products are manufactured under strict compliance with API Annex I 5CT 10th edition.

-

ESP-S™ Protectors

Drilltec’s ESP-S line of protectors is made from high-density polyethylene with Procadd composite material in conjunction with a heavy-duty steel shell which provides an exceptional durability while still offering corrosion protection. This product covers the full length of the pipe thread, preventing hook damage to both the pin and box ends. ESP-S also includes Drilltec’s patented Roll-Over Bumper to protect the leading edge of the pin or box, which in the case of severe impact would damage the connection.

-

TJP™ Protectors

Drilltec’s TJP thread protectors provide reliable and sustainable protection for drill pipe and drill collars with high-impact resistance that exceeds all API performance standards. These products offer complete thread engagement to prevent the protector from stripping or vibrating off the pipe. The TJP product line provides maximum protection for tool joint threads and seals that are sensitive to bi-metal corrosion by utilizing Drilltec’s PROCADD composite material. The lightweight design also reduces overall freight costs without compromising strength or durability.

-

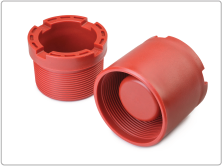

STP™ Protectors

STP protectors are designed to meet customer requirements for both API and premium connections. The protectors are produced with Drilltec’s patented PROCADD composite material to precisely fit tubular connections and provide resistance to inclement conditions during storage and transportation of pipe. STP API threads exceed the API requirements in length, offering superior protection versus competitive thread protection products.

-

SSP™ Protectors

The SSP is Drilltec’s economical alternative for protecting API connections. SSP is also manufactured with high-density polyethylene with PROCADD composite material for high performance. SSP is manufactured as either closed end non-liftable or as closed end liftable for tubing and casing.

-

Drilltec Advanced Composite

Technology (Act™) Protectors

Drilltec's ACT thread protector is manufactured to exceed Annex I 5ct 9th edition requirements. The ACT protectors are made of Drilltec’s patented composite resin blend PROCADD, which provides an unmatched combination of lightweight, strength and durability. ACT offers protection for high-alloy tubular products that typically would be susceptible to bi-metal corrosion.

-

Line Pipe Protectors (LPP™)

Drilltec’s LPP products are specifically manufactured with Procadd composite material and designed with substantially more surface area to provide additional protection against exposure to impact, corrosion and UV elements associated with line pipe. The line pipe protector is equipped with a recessed, closed-end design to keep the inside of the pipe dry and clean while supporting lifting capabilities by lifting hooks. The LPP products also have protection via a heavy-duty, internal bumper that protects bevel ends.

-

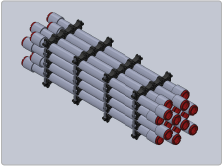

Resist-All Packaging (RAP) Systems

Drilltec developed Drilltec’s proprietary packaging system RAP, as an innovative concept and approach for the handling and transportation of pipe. The RAP™ system delivers versatility through its lightweight, strength, and ease of installation. Drilltec manufactures its resist-all packaging systems in five categories: the RAP*, ECONO-RAP*, LE-6*, LE-12**, and custom designed systems.

RAP is a system of segments comprised of galvanized rectangular steel tube, encapsulated in polyethylene. Each segment is connected and secured to the next with a steel bolt. The protective systems are available for API or premium tubing and casing with sizes ranging from 2 3/8” to 9 5/8”. The RAP systems can be stacked and its design allows for easy lifting by forklift, slings, or endless slings. As with all Drilltec RAP packaging systems, the package is secured using a standard torque wrench for ease of field assembly or disassembly.

* 6 metric ton safe working load

** 12 metric ton safe working load

-

ECONO-RAP™ Packaging Systems

Drilltec’s ECONO-RAP pipe packaging system was developed in 1988 as a more economical solution to pipe handling, transportation, and storage needs. Unlike the traditional RAP™ system that is secured with steel bolts, the ECONO-RAP utilizes durable polyester straps to connect each segment. The straps are tightened for security and provide additional weight savings while safely securing the pipe. The ECONO-RAP is made with the same steel-reinforced, high-density PROCADD composite material.

* 6 metric ton safe working load

-

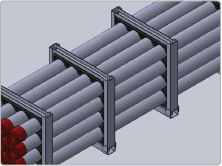

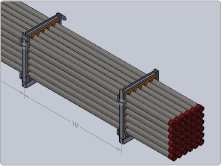

LE-RAP™ Packaging Systems

The LE-RAP packaging system is Drilltec’s most heavy-duty pipe protection system that further secures pipe and provides the same lifting capabilities as the RAP system. Included in the LE-RAP line are the LE-6* and LE-12** systems, which are certified for 6 metric tons or 12 metric tons depending on specific needs. In addition to the PROCADD composite segments used in other Drilltec RAP systems, the LE-RAP utilizes four galvanized steel frames and two are equipped with lifting eyes. In addition to the lifting eyes, the packaged pipe can be lifted using a forklift or slings.

* 6 metric ton safe working load

** 12 metric ton safe working load

-

Custom Packaging Systems

Packaging systems can be custom designed and manufactured by Drilltec to meet specific customer needs. All custom packaging systems come equipped with lifting eyes and use the same patented technology as other Drilltec systems. Custom systems also provide the option for neoprene-lined segments for externally coated pipe.

*** All Rap Packaging systems are designed with a specific safe working load limits

that should not be exceeded.

-

Pipe Stabbing Guides

Drilltec stabbing guides are manufactured using Drilltec’s advanced composite technology to prevent damage to tubing, casing, and drill pipe during the stabbing process. The stabbing guide uses a tapered composite bumper to protect the pin nose and coupling, metal seal on connections, shoulder of the drill pipe, and the pin nose coating. The composite guides are reinforced with metal housing inserts and feature replaceable bumpers and inserts.

-

Secure Tubular Lifting Systems

Drilltec’s revolutionary lifting system makes previous lifting methods obsolete. STLS assures safer work conditions as well as eliminating the damage associated with current lifting methods.

STLS (Secure Tubular Lifting System) is another example of Drilltec’s ongoing leadership in Tubular goods protection.

-

Other Products & Services

In addition to Drilltec’s core products in thread protection and pipe packaging, it utilizes its patented technology and manufacturing capabilities to produce complementary products and services. Other Drilltec products include pipe stabbing guides, bumper rings, and a fully developed line of non-metallic marine products.

-

Drilltec Marine Division

Drilltec’s Marine division manufactures marine products that protect and preserve your boating investment through composite technology.

Drilltec Marine Division’s range of products includes protection components for both marine shore power systems and marine water intake strainer systems. Our unique products are compounded with proprietary materials formulated to solve specific marine maintenance problems.

Our patented technology has influenced the Oil & Gas industry standards for protection of OCTG products against damage caused by corrosion and impact since 1979. We now bring this advanced technology to the marine industry to preserve and protect your vital boating assets.

Drilltec is a member of the National Marine Manufacturers Association.